Ningbo fudu automation equipment co. LTD

Contact: Mr. Fu

Phone:13566606880

Tel:0574-23709308

Fax:0574-23709318

Website:www.nbfud.com

Website: en.nbfud.com

E-mail:fdsc@fudunb.com

Add: lane 266, erheng road, ningfeng north road industrial zone, changhe town, cixi city, zhejiang province

Regardless of the press machining activities and the use of molds, we use a variety of molds to make products, so the mold in the stamping process plays an important role.Now let's look at the process characteristics of a continuous stamping die.The use of the mold needs to pay attention to it.This is the concern of the production and processing personnel.Let's see.Continuous stamping die production process characteristics

The feature of continuous stamping in mould production

After completing a set of molds, zhejiang textile machinery accessories can produce many different products and components.However, for the manufacture of the mold itself, its production scale is only single piece production, and the main feature of its production process is that the blank part of the mold is usually made of wood mold, manual sand casting and free forging, with low blank precision.Handling quotas are large.After that, it is necessary to carry out fine processing on the mould so that the mould produced can produce good quality parts in the stamping process.

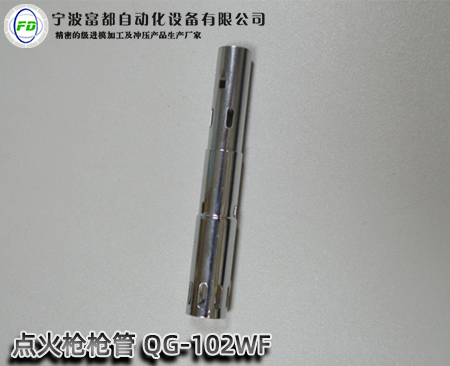

In addition to general purpose machine tools, manufacturers of igniter metal tubes also use die components.Such as lathe, universal milling machine, internal and external grinder, surface grinder processing, also use university, mute professional processing equipment and machine tools, such as contour planer, electrochemical piercing machine, wire cutting machine, molding grinder machine.For the processing of the mould parts of the continuous mould, more than half of them use the universal fixture, and ensure the dimensional accuracy by marking and appropriate cutting methods.In order to reduce the cost, few professional fixture processing.Continuous stamping die production process characteristics

Through the introduction of the article, we understand the characteristics of continuous stamping die in the production and processing activities, lighter hood continuous mold is the main production mold, can be used to produce a variety of products.

Continuous molding method: 1).Upsetting table: upsetting table is mainly used to increase the cross section area of the blank, reduce the size of its height direction, forging the round blank.2).Flat surface: continuous forming plane mainly flattens the round billet and increases its width to reduce its thickness, forging rectangle or casting billet.3).Long die: long die is mainly used to reduce the cross-sectional area of part of the blank length and increase its length.

Semi-closed compression mold, also known as semi-overflow compression mold, has the following structural characteristics: 1.A feed cavity with a section size larger than the section size of the cavity is provided above the cavity making it easy to ensure the quality of the inherent plastic components.2. The punches in the feed room shall fit with the clearance of H9 / f9.3. There is a ring pressing surface with a width of 4.5mm at the boundary between the feed chamber and the cavity.The punch is pressed down to contact with the pressed surface, so it is easy to ensure dimensional accuracy in the direction of the height of the plastic parts.4. The flash is smaller than the open compression mold in the pressing process, so plastic parts with basically the same height can be obtained in mass production.