Ningbo fudu automation equipment co. LTD

Contact: Mr. Fu

Phone:13566606880

Tel:0574-23709308

Fax:0574-23709318

Website:www.nbfud.com

Website: en.nbfud.com

E-mail:fdsc@fudunb.com

Add: lane 266, erheng road, ningfeng north road industrial zone, changhe town, cixi city, zhejiang province

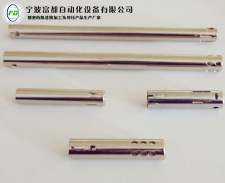

With the continuous improvement of technical level, the production of progressive mould is also developing towards lean.Most parts are produced through stamping and processing molds, so the quality of molds can affect the production and processing of parts.Progressive die is a form of mold, its standard level represents the following aspects, mold manufacturing cycle, manufacturing cost, precision, of course, not limited to these aspects.Make excellent mold products, choose ningbo fudu automation equipment co., LTD., let us know it.

Standard level of progressive die for stamping

1. Mold manufacturing cycle

The manufacturing cycle of mould reflects the technical level and organizational management level of mould production.When manufacturing molds, ningbo precision stamping parts as far as possible to shorten the mold manufacturing cycle.By using the method of mould and computer aided design of nc machine tool, the mould manufacturing cycle can be shortened by more than 60%.

2. Mold manufacturing cost

The lower the mold cost, the higher the mold technology level.This requires that in addition to reasonable selection of mold materials, it is also necessary to reduce the processing time and various costs when manufacturing progressive mold.

3. Mold accuracy

Mold precision can be divided into parts precision and precision to achieve mold efficiency, such as surface parallelism, perpendicularity and guide fit.Machining accuracy is limited by machining method, machining equipment and its own precision.Generally speaking, the precision of the die mainly refers to the size precision of the punch and the die cavity.The level of standardization of progressive die

Through the above description, we have understood several aspects of mold standardization requirements.Of course, there are also factors such as service life, its processing is affected by many factors.Buy good quality, price preferential mold products, came to ningbo fudu automation equipment co., LTD., advanced mold stamping processing technology, get everyone's affirmation.Everyone knows that we use many molds in our lives.Because we want to make a good product, we need to design carefully again and again.Let's do a simple example today, hope.Everyone can do research with us, this is the design point of progressive mould.What does it look like?We will briefly list a few.I hope everyone will read the following carefully.We'll see in a second. Let's see.

What are the design points of progressive die?

1. Die radius of progressive die

The radius of the progressive die is always in all directions.Otherwise, bending, blank will slide, product deviation will be affected, should choose the accuracy and size.When advanced in design, the radius of the curved fillet should be appropriately chosen and not too large or too small.The radius of the Angle of the metal tube of the igniter causes local deformation or thinning of the product, which affects the quality and surface roughness of the product.

2. Prevent blank deviation during bending

When designing molds, the following precautions should be taken in the mining area to prevent blank deviation during bending: the mold should be equipped with spring pressure device, and it should be noted that the leather should be partially pressed with elasticity before bending, and then bent.

3. Prevent deformation when bending

For the design of multi-angle progressive die, multi-angle and multi-angle bending must be carried out at different times.Precision metal stamping parts should be designed to have the effect of correcting bending when the bottom dead point of die bending is designed.The design of die structure should take full account of eliminating springback.When designing the positioning device, the necessary measures must be taken to make the blank as much as possible during the bending process.

That's all we have for you.I hope everyone can understand and understand our introduction in detail, the die radius of progressive die, deviation of blank during bending and preventing bending.Deformation and so on need to thoroughly understand, so you want to know anything else, please contact our progressive mold company, we will provide you with a detailed introduction.