Ningbo fudu automation equipment co. LTD

Contact: Mr. Fu

Phone:13566606880

Tel:0574-23709308

Fax:0574-23709318

Website:www.nbfud.com

Website: en.nbfud.com

E-mail:fdsc@fudunb.com

Add: lane 266, erheng road, ningfeng north road industrial zone, changhe town, cixi city, zhejiang province

With the development of die processing, reasonable use of die is still necessary.After all, there are many types of mold products, so the processing technology requirements are also very high.What is the main stage of mould extrusion?Preparation, pressure and discharge phases are all worth watching.Now, let us look at ningbo fudu automation equipment co., LTD. Mold processing.Everyone is very curious about this, let's take a look at the small series.

Analysis die extrusion stage

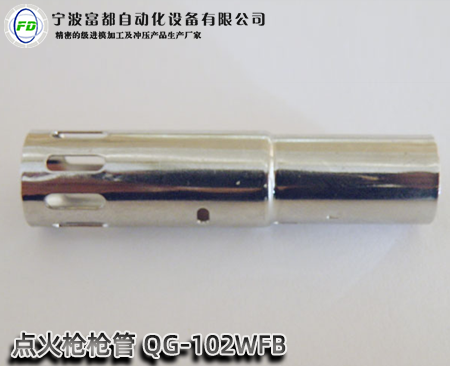

In the process of mold processing, some molds need a separate feed chamber, mold with pouring system.When working, the igniter tube first closes the die and then presses into shape.

Forming process principle is mainly divided into three stages.

1. In the preparation stage, after weighing the plastic powder, pour it into the feeding room and heat it to the plastic state.

2. During the pressure application phase, when the pressure column moves down on the hydraulic press, the pressure into the feed chamber is applied to the molten plastic and is injected into the mold cavity at a high speed through the mold's casting system, ensuring insulation and hardening after a period of time.

3. In the unloading stage, after the mold is opened, special unloading mechanism is adopted for the ignition barrel wholesale to push out the plastic parts, clean the cavity, feed cavity and gate, and prepare for the next stroke.The extrusion forming stage of metal tube die for igniter was analyzed

This paper mainly shares three elements of progressive die extrusion molding.Accordingly, the processing of mould cannot be loosened in each stage, kitchen provides accessory cover plate otherwise wallop still is bigger.All kinds of high-quality mold selection, good quality, the price is also very affordable, skilled mold processing selection my company, will not let you down.

1).The volatilization point is very low.When the temperature is between 100℃ and 150℃, the diluent can evaporate quickly without increasing the gas in the cavity.

2).The coverage is good, the film layer forms at high temperature after the diluent volatilizes, but the accumulation is not easy, and the mold is easy to clean.

3).It does not cause corrosion to molds and castings.

4).Environmental pollution as small as possible, that is, no odor, no precipitation or decomposition of harmful gases.

5).Stable performance, non-volatile in air, no precipitation or decomposition during specified storage period.

6).The preparation is simple, the source is abundant and the price is low.