Ningbo fudu automation equipment co. LTD

Contact: Mr. Fu

Phone:13566606880

Tel:0574-23709308

Fax:0574-23709318

Website:www.nbfud.com

Website: en.nbfud.com

E-mail:fdsc@fudunb.com

Add: lane 266, erheng road, ningfeng north road industrial zone, changhe town, cixi city, zhejiang province

Structural features of progressive die:

1. The mould is composed of upper mould, lower mould and mould sleeve, and guided by guide column;

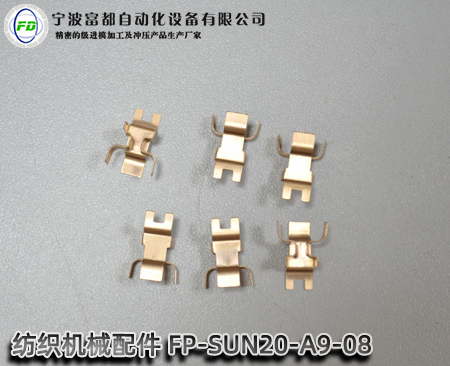

2. There is a punch in the upper die fixing plate and a screw is connected to the upper die plate;Textile machinery parts

3. The concave die with cone hole is loaded into two semi-tapered concave die with cavity hole in the middle, and the two semi-circular concave die has two locating pins for positioning;

4, the lower die is composed of the lower die fixed plate with a core and another core;

5, unloading part by the rod and rod pad composition, after the parts and products molding, first use special mold unloading work to pry open the upper mold, and then use the rod to push the two semi-cone concave mold out of the mold, so that the progressive mold can be separated from the products.

Progressive molding process: ignition barrel wholesale

1. In the preparation stage, after weighing the plastic powder, first pour it into the feeding room and heat it to a plastic state.During the pressure stage, when the press column moves down on the working table of the hydraulic press, it enters the feeding room to press the molten plastic, and penetrates into the mold cavity at a high speed through the casting system of the mold, and after a certain period of time, it is guaranteed to be insulated and hardened.

2. In the unloading stage, after the mold is opened, the special unloading mechanism is used to push out the plastic parts, clean the mold cavity, feeding room and runner, and prepare for extrusion in the next stroke.