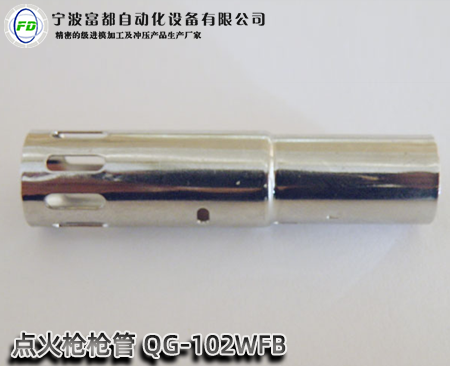

Ningbo fudu automation equipment co. LTD

Contact: Mr. Fu

Phone:13566606880

Tel:0574-23709308

Fax:0574-23709318

Website:www.nbfud.com

Website: en.nbfud.com

E-mail:fdsc@fudunb.com

Add: lane 266, erheng road, ningfeng north road industrial zone, changhe town, cixi city, zhejiang province

Layout design should follow the principles

Multi-station progressive die layout, in addition to the general die layout principles, should also consider the following points:

1) the blank template (3-5 pieces) can be made for stamping parts, and the blank template can be tested and arranged repeatedly on the drawing surface. After the preliminary scheme is determined, the punching, incision, scrap cutting and other separation positions can be arranged at the beginning of the layout drawing, and then the forming positions can be arranged successively at the other end, and finally the parts and carriers can be separated.Ningbo precision stamping parts in the arrangement of work, to avoid punching small half hole as far as possible, to prevent the punch force uneven and broken.

2) punch hole and punch process guide hole are generally arranged in the first working station.The second station sets the guide pin on the belt material guide pin, in the later station, the plastic lighter windshield to see the number of stations and easy to change the station set guide pin, but also in the later station every 2 ~ 3 stations set guide pin.According to the positioning accuracy of the stamping strip, the third station can set up the wrong feeding detection device of the feeding step.

3) if the number of holes on the stamping parts is large and the position of holes is too close, the holes can be rushed out at different working positions, but the holes cannot be deformed due to the influence of subsequent forming processes.For holes with higher requirements on relative position accuracy, synchronous flushing should be considered. When synchronous flushing cannot be achieved due to the limitation of mold strength, measures should be taken to ensure the relative position accuracy of holes for subsequent punching.Complex type hole, can be decomposed into a number of simple hole step out.

4) in order to improve the strength of the insert, unloading plate and fixed plate of the die and ensure that the installation position of each formed part does not interfere, empty stations can be set in the layout, and the number of empty stations can be determined according to the requirements of the mold structure.

5) the selection of forming direction (up or down) should be conducive to the design and manufacturing of the mold and the smooth feeding of the material.If the stamping action is different from the stroke direction of the punch slider, the inclined slider, lever and pendulum can be used to change the forming direction.