Ningbo fudu automation equipment co. LTD

Contact: Mr. Fu

Phone:13566606880

Tel:0574-23709308

Fax:0574-23709318

Website:www.nbfud.com

Website: en.nbfud.com

E-mail:fdsc@fudunb.com

Add: lane 266, erheng road, ningfeng north road industrial zone, changhe town, cixi city, zhejiang province

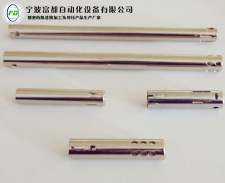

What is high-speed stamping die what is high-speed stamping die, a lot of people do not know, it is a kind of mold used to make electrical appliances, help the manufacturing of electrical appliances.So what is the composition of the high speed stamping die?This is very helpful to our production activities.I think everyone is curious about it.Igniter metal tube let us look at small make up!

High-speed stamping die is an indispensable process equipment in the process of stamping production.Die structure must meet the requirements of stamping production.It must not only mark qualified parts, but also meet the needs of mass production.Easy to operate, long service life.And can be easily manufactured and repaired.Working parts mainly include punch, die, punch and so on.The function of the locating part is to determine the correct position of the sheet or blank relative to the stamping to ensure the quality of the stamping.The guide parts mainly ensure the precise position of punch and die, including guide sleeve, guide column, guide plate, etc.What is a high speed stamping die

In general, the working parts of the mould, locating parts, unloading and pushing parts become the process parts of the mould, guiding parts, supporting and supporting parts, fastening parts and buffer parts become the auxiliary parts of the mould.In fact, for each set of molds, they must be a complete and independent whole, composed of various parts.Basic classification can be made according to the functions and requirements of each part.For the same function, due to different conditions of use, the structure is diverse.

Textile machinery parts manufacturing factory progressive die stamping advantages are high production efficiency, short cycle, low human consumption, especially suitable for the mass processing of products.After understanding the product design drawing, first calculate the product size according to the formula.Size calculation must be accurate, otherwise it will affect the qualified rate of the product.In the process of designing the sample drawing, if the layout drawing is confirmed, the mold structure is basically released.Progressive mold should be considered in layout, attention to detail.For example, when assigning each part of a workstation, consider not only stamping, folding, but also insertion.For products that are easy to cut in the molding process, pay attention to the smoothness of the work to ensure quality.Therefore, no matter which method is used to take out the parts, it should be carried out after the study of the designer to ensure the smooth entry and exit of the steel strip and reduce the zero cost of metal.

This paper mainly introduces the application of high-speed stamping die.Therefore, we know that it is easy to operate, long service life, and have a certain understanding of the common parts of the stamping die.If you are interested in our introduction, we will bring you more wonderful information in the future, please support!