Ningbo fudu automation equipment co. LTD

Contact: Mr. Fu

Phone:13566606880

Tel:0574-23709308

Fax:0574-23709318

Website:www.nbfud.com

Website: en.nbfud.com

E-mail:fdsc@fudunb.com

Add: lane 266, erheng road, ningfeng north road industrial zone, changhe town, cixi city, zhejiang province

What is called precision stamping and general stamping processing of the lighter hood is the power of conventional or special stamping equipment, so that the plate directly in the mold by deformation force and deformation, so as to obtain a certain shape, size and performance of the product parts production technology.Sheet material, mould and equipment are the three elements of stamping processing.Stamping is a kind of metal cold deformation processing method.Therefore, it is called cold stamping or sheet metal stamping, or simply stamping.It is one of the main methods of metal plastic processing (or pressure processing) and also belongs to material forming engineering technology.The die used in stamping is called stamping die, die for short.Die is the material (metal or non-metal) batch processing into the required punching tools.Punching die is very important in stamping, without the required punching die, batch stamping production is difficult to carry out;Without advanced die, advanced stamping process can not be achieved.Stamping process and die, stamping equipment and stamping materials constitute the three elements of stamping processing, only they can be combined to get stamping parts.Compared with other methods of mechanical processing and plastic processing, stamping processing has many unique advantages both in technology and economy.

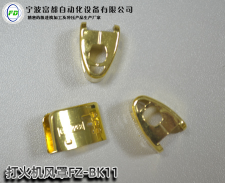

The main performance is as follows: lighter windshield

(1) the production efficiency of stamping processing is high, and easy to operate, easy to achieve mechanization and automation.This is because the stamping is to rely on the stamping die and stamping equipment to complete the processing, the stroke of the ordinary press can be dozens of times per minute, high speed pressure can be up to hundreds of times per minute or even more than a thousand times, and each stroke may get a punch.What is precision stamping and common stamping

(2) when stamping, the die ensures the size and shape accuracy of the stamping parts, and generally does not destroy the surface quality of the stamping parts, and the life of the die is generally long, so the quality of stamping is stable, good interchangeability, with the "same" characteristics.Precision stamping parts manufacturers

(3) stamping can be processed into a large range of size, shape more complex parts, such as small to the clock stopwatch, large to the car rail, covering parts, and so on, plus the cold deformation hardening effect of stamping materials, the strength and stiffness of stamping are higher.

(4) generally, there is no chip or scrap for stamping, the material consumption is less, and no other heating equipment is needed, so it is a kind of energy-saving processing method, and the cost of stamping parts is lower.Due to the advantages of stamping, stamping processing is widely used in various fields of national economy.For example, in aerospace, aviation, military, machinery, agricultural machinery, electronics, information, railway, posts and telecommunications, communications, chemical, medical equipment, daily electrical appliances and light industry sectors have stamping processing.Not only is it used throughout the industry, but everyone is directly involved in stamping products.There are many large, medium and small stamping parts on airplanes, trains, cars and tractors.Car body, frame and ring parts are stamping out.What is called precision stamping and general stamping according to the survey statistics, bicycles, sewing machines, watches are 80% stamping parts;Television sets, radio recorders, video cameras are 90% stamped;There are metal food canes, steel boilers, enamelled bowls and stainless steel tableware, all of which are stamped with moulds;Even computer hardware is missing stamping parts.But, the die that stamping machining USES has special use commonly, sometimes a complex part needs several sets of die to be machined form, and die