Ningbo fudu automation equipment co. LTD

Contact: Mr. Fu

Phone:13566606880

Tel:0574-23709308

Fax:0574-23709318

Website:www.nbfud.com

Website: en.nbfud.com

E-mail:fdsc@fudunb.com

Add: lane 266, erheng road, ningfeng north road industrial zone, changhe town, cixi city, zhejiang province

1. The development point of stainless steel wire musket barrel spring design, material and processing

(1) the strength of austenitic stainless steel wire is better than ferrite structure, and its corrosion resistance is better than martensite structure.

(2) wire drawing at low temperature or nitriding at low temperature can improve steel wire strength.The microstructure of martensite is unstable when heated, and the martensite can be formed by drawing wire in cryogenic liquid nitrogen, which can obtain high thermal strength.This kind of steel wire has been used in the United States and Japan, but at present can only handle less than 1mm steel wire.

(3) precision springs in electronic equipment shall be non-magnetic, and such steel wire shall not generate hidden needle martensite during drawing processing.To do this, add N, Mn, Ni, and so on.To meet this demand, the United States developed AUS205(0.15 c-17cr-1ni-15mn-0.3n) and YUS(0.17 c-21cr-5ni-10mn-0.3n).Because of the increase of Mn content, hidden needle martensite will not be produced in processing.After solid solution treatment, strength up to 2000Mpa, high fatigue performance, better than SUS304.

2. Improve the material purity of the ignition gun barrel for high-strength materials, strictly control the inclusion, and improve the purity to ensure its performance.Oxygen levels such as valve spring material, at present has reached 20 x 10 ˉ 6 development.Ignition barrel spring design, material and processing

The surface quality of materials has a great influence on the fatigue performance.In order to ensure the quality of the surface, the surface layer 0.1mm will be used for materials with special requirements by skinning process.Eddy-current testing is used for defects with a depth of 0.5mm.For the uneven surface produced in the process of wire drawing, the surface roughness can be reduced to Ra=6.5 ~ 3.4 microns by electrolytic grinding.

4. The development of electroplating steel wire in special circumstances, in addition to the spring characteristics, but also requires corrosion resistance, electrical conductivity and other additional properties, most of the use of electroplating technology to solve.Some stainless steel wire and piano wire corrosion resistance equivalent to galvanized corrosion resistance, if a layer of ZnAl(5%) alloy, the corrosion resistance can be improved by about 3 times.For stainless steel wire or piano wire with resistance performance requirements, the diameter of the wire is less than 0.4mm, the diameter of the wire is larger than 0.4mm, the internal is copper, the external is stainless steel material.General piano steel wire plated 5 microns thick Ni, can improve its electrical conductivity.

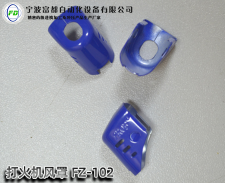

In general, processes that can harden a material's surface to form residual stresses (such as shot peening and surface nitriding) can improve fatigue strength.At present, non-electrolytic Ni plating is being studied. 7% of P can be precipitated out with PNi by heating (300 ~ 500℃), which can improve vickers hardness up to HV500.After shot peening, the hardness can be increased by 10% if Ni plating is heated below 300℃.Precision lighter hood

5. Development of shape memory alloy a unidirectional shape memory alloy with promising application in spring, 50ti-50ni has the best performance.Spring made of shape memory alloy, retractable by temperature.It is mainly used in the control system of constant temperature, constant load and constant deformation.Because is to rely on the spring stretching to push the actuator, so the spring work stress changes greatly.

The elastic modulus of ceramics is high, the fracture strength is low, suitable for the place of little change.At present, we are developing ceramics with good heat resistance, wear resistance and insulation.Superplastic zinc alloy (SPZ) is used for its high strength at room temperature.In addition, there is high strength silicon nitride, high temperature resistance, up to 1000℃.However, ceramic spring is not suitable for working under impact load.Textile machinery parts

Glass fiber reinforced plastic (GFRP) plate springs have been widely used in Britain, the United States and Japan, in addition to the horizontal suspension, but also can be used in special light vehicles, such as racing car vertical suspension.At present, carbon fiber reinforced plastic (CFRP) suspension spring is developed successfully, which is 20% lighter than the metal plate spring.